ERP search and reporting functionalities thrive on quality data in order to provide accurate, real-time statistics and data visibility. For this reason, addressing data quality concerns prior to ERP implementation should always be a priority in the early stages of any project.

So if this is the case, then why does data quality seem to be such an overlooked area?

Well, many companies still overlook this area due to a misunderstanding on how the ERP system and data are used. In some cases, companies are well aware of their data quality issues yet don’t understand the value and benefits that a data cleansing project will deliver to all units of the business. In other cases, companies believe that an expensive, new ERP system will be the single answer to all of their problems, only to realize six months down the road that they still cannot conduct basic part searches and transactional reports.

There may not be a single answer to the problem but improving data quality through cleansing, standardization and enhancement is usually a great place to start. A typical data cleansing project will establish client-specific data standards that will consistently be used to structure materials data moving forward.

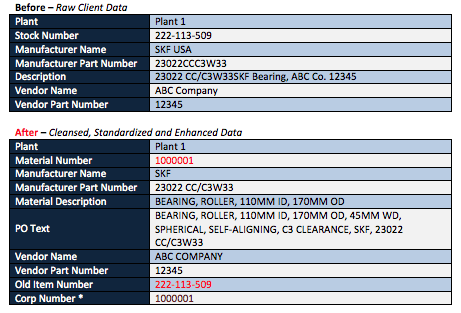

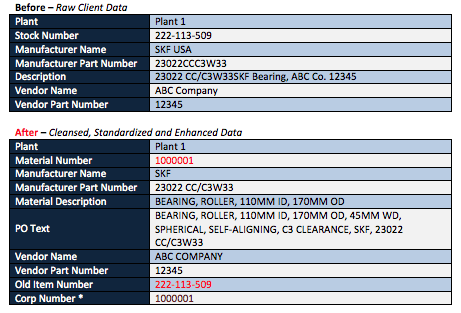

Before migrating legacy data to the new ERP system, each and every item will be cleansed, standardized and enhanced, where possible, according to pre-defined client standards. During the cleansing process, manufacturer names and part numbers will be segregated and standardized, while legacy item/ID numbers remain intact for future reference. After the cleansing process is complete, duplicate items are identified by direct match and fit-form-function similarity. Direct duplicates include two or more items possessing the same manufacturer name, part number and description, whereas, fit-form-function duplicates include two or more items that possess different manufacturer names and part numbers but have the same fit, form and function/description.

Dependent on client preference, items can be classified by various international and company-specific codification systems, enabling greater reporting capabilities. Furthermore, the final deliverable will be formatted to suit specific ERP requirements, including field name, type and character limitation.

To illustrate the results of data cleansing, the following sample shows what raw client data looked like before and after being cleansed, standardized and enhanced.

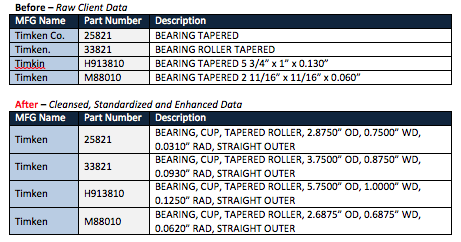

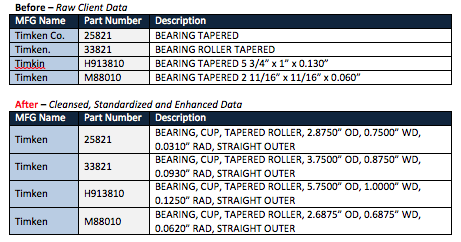

To further illustrate data consistency, the following before and after sample shows the common standardization within a specific product group.

To further illustrate data consistency, the following before and after sample shows the common standardization within a specific product group.

No matter how expensive, functionality-rich or industry-recommended an ERP application may be, the reality is that the software is only as good as the data flowing through it. While data cleansing may add cost to an already expensive ERP implementation, the project will pay for itself almost immediately through the identification of excess and duplicate inventory, improved maintenance efficiency, elimination of false stock-outs, reduced equipment downtime and numerous other ERP benefits. So if you want to capture maximum return on your ERP investment, the key is to prioritize data quality.

No matter how expensive, functionality-rich or industry-recommended an ERP application may be, the reality is that the software is only as good as the data flowing through it. While data cleansing may add cost to an already expensive ERP implementation, the project will pay for itself almost immediately through the identification of excess and duplicate inventory, improved maintenance efficiency, elimination of false stock-outs, reduced equipment downtime and numerous other ERP benefits. So if you want to capture maximum return on your ERP investment, the key is to prioritize data quality.

For more information on Data Cleansing and related services, visit www.imaltd.com or contact info@imaltd.com.

So if this is the case, then why does data quality seem to be such an overlooked area?

Well, many companies still overlook this area due to a misunderstanding on how the ERP system and data are used. In some cases, companies are well aware of their data quality issues yet don’t understand the value and benefits that a data cleansing project will deliver to all units of the business. In other cases, companies believe that an expensive, new ERP system will be the single answer to all of their problems, only to realize six months down the road that they still cannot conduct basic part searches and transactional reports.

There may not be a single answer to the problem but improving data quality through cleansing, standardization and enhancement is usually a great place to start. A typical data cleansing project will establish client-specific data standards that will consistently be used to structure materials data moving forward.

Before migrating legacy data to the new ERP system, each and every item will be cleansed, standardized and enhanced, where possible, according to pre-defined client standards. During the cleansing process, manufacturer names and part numbers will be segregated and standardized, while legacy item/ID numbers remain intact for future reference. After the cleansing process is complete, duplicate items are identified by direct match and fit-form-function similarity. Direct duplicates include two or more items possessing the same manufacturer name, part number and description, whereas, fit-form-function duplicates include two or more items that possess different manufacturer names and part numbers but have the same fit, form and function/description.

Dependent on client preference, items can be classified by various international and company-specific codification systems, enabling greater reporting capabilities. Furthermore, the final deliverable will be formatted to suit specific ERP requirements, including field name, type and character limitation.

To illustrate the results of data cleansing, the following sample shows what raw client data looked like before and after being cleansed, standardized and enhanced.

To further illustrate data consistency, the following before and after sample shows the common standardization within a specific product group.

No matter how expensive, functionality-rich or industry-recommended an ERP application may be, the reality is that the software is only as good as the data flowing through it. While data cleansing may add cost to an already expensive ERP implementation, the project will pay for itself almost immediately through the identification of excess and duplicate inventory, improved maintenance efficiency, elimination of false stock-outs, reduced equipment downtime and numerous other ERP benefits. So if you want to capture maximum return on your ERP investment, the key is to prioritize data quality.

For more information on Data Cleansing and related services, visit www.imaltd.com or contact info@imaltd.com.

For more information on Data Cleansing and related services, visit www.imaltd.com or contact info@imaltd.com.